Aspirated Systems for one or two measured gases

Sampling of measured gas and transmitter combined in one wall mounted housing.

Particularly suitable for biogas application

Features

-

Transmitter:

· Number: 1 (AS-1, AS-1 Biogas) or 2 (AS-2)· Types freely selectable (not included in scope of delivery) -

Control Unit:

· Externally, e. g. by ExTox Control Unit -

Sampling of Gas:

· Gas suction pump· Electrical flow monitoring by means of pressure difference measurement: in case of under-scale of the minimum flow,fault indication is issued by breaking the transmitter output signal (4…20 mA)

· 2 screw-in connections (4/6 mm) for inlet and outlet of measured gas at the bottom of the housing· 1 screw-in connections (4/6 mm) for condensate outlet at the bottom of the housing (AS-1 Biogas only) -

Conditioning of Measured Gas:

· Condensate trap with peristaltic pump 340 ml/h (AS-1 Biogas only)

· Flame Arrestor Ex IIG IIB3 in the gas inlet (AS-1 Biogas only) -

Hosing::

· PE/PP

Operation Conditions

-

Distance for Suction: When using hose 4/6 mm(inner/outer Ø: 4/6 mm)

· Standard: ≤ 50 m

· High performance gas suction pump (Option): ≥ 100 m -

Operation Temperature:

· -10 °C bis +40 °C· Additional limitations due to used transmitters have to be considered

· In general an installation outside is not recommend, as in principle measuring accuracy and lifetime are influenced in a negative way. In case it is however necessary, please contact ExTox to design a suitable type -

Pressure at Suction Point (relative to ambient pressure):

· Standard: up to ±50 hPa

· High performance gas suction pump (Option): up to ± 100 hPa

Mechanical Features

-

Dimensions (Height x Width x Depth):

· 380 mm x 300 mm x 155 mm (AS-1)

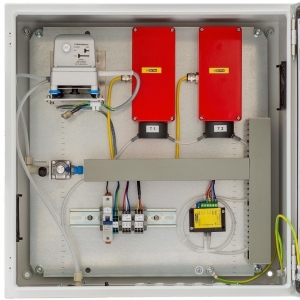

· 500 mm x 500 mm x 300 mm (AS-1 Biogas, AS-2) - Housing: Wall mounted housing with door, mounting plate, foamed-in door sealing, 1 cam lock

- Material: Steel, powder-coated in textured RAL 7035

- Ventilation: 2 fans, cross-flow, speed monitored (AS-1 Biogas, AS-2 only)

-

Storage Temperature:

· -25 °C bis +60 °C

· Additional limitations due to used transmitters have to be considered

Electrical Features

-

Power Supplies:

· External: 230 V AC (Pump)

· From control unit: 24 V DC (Transmitter) -

Cable Gland: At the bottom of the housing

· 1 gland M20 x 1.5 (diameter of cable 7-13 mm)

· 5 glands M16 x 1.5 (diameter of cable 5-10 mm) -

Terminal Assignment: Double stock clamps for

· Power Supply (230 VAC fused with 6 A)

· Transmitter (+ 24 VDC, GND, 4…20 mA)

Optionen

-

ExTox-Transmitter:

· Depending on type of measured component a suitable transmitter can be chosen out of the ExTox programme. -

ExTox-Control Unit:

· The measuring signal supplied by the Aspirated System can be evaluated by every ExTox-Control Unit. -

Flame Arrestor:IIG IIB3 (Art.-No. 940250) or IIG IIC, e. g. for hydrogen, (Art.-No. 940251):

When sampling in hazardous areas the gas flow inside the Aspirated System is decoupled of the monitored process as far as the danger of explosion is concerned. The flame arrestor is connected to the measured gas inlet. When returning the measured gas into the process (not recommended due to due to technical measurement reasons) another flame arrestor at the measured gas outlet is necessary. Protection class of the flame arrestor shall be adapted to the measured gas. -

High performance gas suction pump:

· Application in case of far distances to the suction point or high pressure difference relative to ambient. -

Condensate trap (great) incl. hose pump 800 ml/h (Art.-No. 940255):

· Used for applications where a great amount of condensate will be formed in the measuring pipe. -

Suction Filter, plastic (Art.-No. 940618):

· Device for gas sampling from the ambient air with a plastic sinter-element for filtering the sampled gas. Mounting at the wall or ceiling. Orientation of sinter-element and hose connector can be chosen variable.

All control units of the ET-Series could be used in combination with all ExTox Transmitters ExSens(-I) and Sens(-I)

Our control units in combination with the ExTox Transmitters comply with the requirements of EN 60079-29-1, EN 45544-1 to EN 45544-3 and EN 50104 for Gas Detection Systems. Furthermore are those in conformity to the European Directives 2014/34/EU (ATEX), 2014/30/EU (EMV), 2014/35/EU (LVD).

Downloads

Here you can download detailed information about our products, applications and systems