Monitoring of air inflated membrane systems at Biogas Plants.

Cost efficient solution for membrane systems with dynamic pressure at the blow-off end. Early recognizing of leakages, in order to avoid cost due to gas loss and danger for staff, plant and environment.

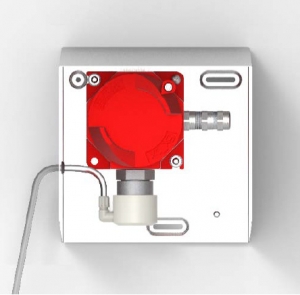

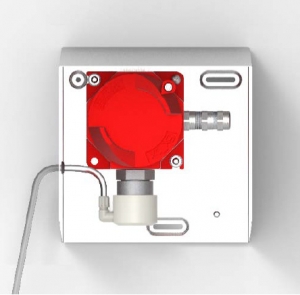

The set consists of an explosion proof transmitter including weather protection cover and all necessary parts for feeding with measured gas.

Features

- Measuring Range: 0 to 5000 ppm Methane

- Measuring Principle: Metall oxyde Semiconductor

- Operation Mode: Continuous Measurement

- Sampling of measured gas: Difference in (dynamic) pressure inside the air inflated system

- Difference(dynamic)Pressure: ≥ 2 hPa (mbar) and ≤ 10 hPa (mbar)

- Maximum distance to the measured gas suction point: ca. 1.5 m

- Connection to measuringConnection to measuringpoint:

· Self-sealing EPDM-rivet-hose adapter

· PE-Hose 6/8 mm, 2 m (cannot be lengthened)

· TL-Measuring adapter for transmitter

- Evaluation measuring signal: ExTox Control Unit or ExTox IMC

Range of Application

- Temperature: -20 °C to 55°C

- Humidity: 10 r.H to 90 r.H (avoid condensation)

- Pressure (surrounding atmosphere): 800 hPa to 1100 hPa

- Weather protection: Stainless steel cover (part of the scope of delivery)

Installation Hints

- The measured gas suction point has to be in air flow direction before the dynamic pressure flap. In comparision to atmospere the dynamic pressure has to be miminum 2 hPa (mbar) and not more than 10 hPa (mbar) at this point.

- The Transmitter TL-5000-STD is installed closed to the blow-off opening. For protection of the transmitter against atmospherical influences, especially direct sun, a weather protection cover is installed. By this a stable measuring behaviour is ensured even on those small methane concentrations. The weather protection cover might not be removed.

- Conneciton of the measuring gas feeding to the transmitter is done by means of a self- sealing EPDM-rivet-hose adapter which is easy to install. Only a drill hole of 24 mm is necessary on the exhaust line. The gas transport to the sensor is ensured by dynamic pressure at the blow-off end. A gas suction pump is not necessary.

- The (non-insulated) measured gas line has to be laid ascending on a minimum length of 30 cm behind the suction point; see Installation Hints on Page 3. It is allowed to shorten the supplied measured gas line, but it might not be lengthened.

- The Transmitter TL-5000-STD has to be installed accessibly for maintenance work.

Mechanical Data

- Weight: approx. 4 kg

- Material:

· Housing: cast aluminium, lacquered

· Sensor block and weather protection: stainless steel

- Enclosure Rating: IP 65 (except gas inlet)

- Storage Temperature: -25 °C to +60 °C

Electrical Data

- Power Supply: 24 ± 6 V DC

- Power Consumption: 80 mA / 2 W

- Interface:

· 4…20 mA, active

· Linear calibration curve

- Max. Load: 500 Ω

- Cable Gland: M 16 x 1.5, diameter of cable 4-8.5 mm

Conformity

- EC-Directives:

· 2014/30/EU (EMC)

· 2014/34/EU (ATEX)

- Type examination Test: BVS 04 ATEX E 066 X (EN 60079-0 und EN 60079-1) incl 1. and 2. Amendment

- Protection: Ex db IIC T4 (-20 °C ≤ Tamb ≤ 60 °C) Gb

- Measuring Functions:

· Measurement technical features designed for detection of small increases of concentration for early recognition of leakages

· Functional features according to Requirements to Gas detection systems DIN EN 60079-29-1

Further applicable Documents

- Instruction Manual ExTox Transmitter ExSens(-I) and Sens(-I)

- Data Sheet Transmitter Series ExSens and Sens: General Installation Hints

(Subject to Technical Changes)

All control units of the ET-Series could be used in combination with all ExTox Transmitters ExSens(-I) and Sens(-I)

Our control units in combination with the ExTox Transmitters comply with the requirements of EN 60079-29-1, EN 45544-1 to EN 45544-3 and EN 50104 for Gas Detection Systems. Furthermore are those in conformity to the European Directives 2014/34/EU (ATEX), 2014/30/EU (EMV), 2014/35/EU (LVD).

Downloads

Here you can download detailed information about our products, applications and systems